16-2000mm PE ipayipi extrusion umugqa

Isicelo

Ipulasitiki yomugqa wepayipi le-HDPE isetshenziselwa ukukhiqiza zonke izinhlobo zamapayipi e-HDPE, njengalezi: ukunikezwa kwamanzi ezolimo & uhlelo lwamapayipi okukhipha amanzi, ukunikezwa kwamanzi okuklama kanye nesistimu yokukhipha amapayipi, uhlelo lwamapayipi okuhambisa igesi, njll.

Amapayipi okucindezela

Amapayipi okuhambisa amanzi nawokuthutha

Amapayipi okusabalalisa negesi okuthutha

Amapayipi asensimini yezimayini

Amapayipi okunisela ezolimo

Ipayipi lokulahla amasimu amakhemikhali nokudla

Amapayipi okuvikela kanye namapayipi ezintambo zikagesi nezintambo zokuxhumana

Amapayipi onqenqema lwe-Fishpond

Incazelo

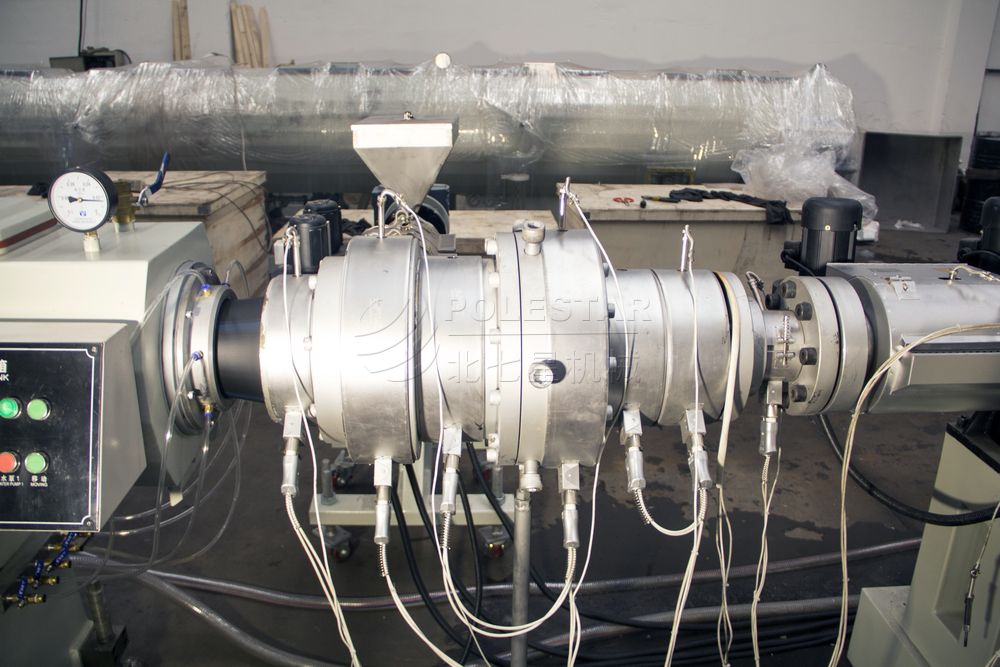

Umshini wolayini wepayipi le-Hdpe unomshini we-hdpe wepayipi extruder, ipayipi iyafa, amayunithi okulinganisa, ithangi lokupholisa, ukukhipha, i-cutter, isitaki/ikhoyili nazo zonke izinto eziphathelene nokuxhumana.

I-Hdpe plastic pipe extrusion line ikhiqiza amapayipi anobubanzi obusuka ku-20 kuye ku-1600mm ezintweni ezihlukahlukene, njenge-HDPE, PP-H njll.

Umshini wamapayipi we-Hdpe uwuhlelo oluncanyelwayo lokudonsa igesi, ipayipi lamanzi kanye nepayipi lokunisela lezolimo phakathi kwedolobha nedolobhana.

Ishadi le-Pipe Vacuum Tankflow ye-Hdpe Pipe Extrusion Line

Impahla eluhlaza + isithako → ukuxuba → umshini wokuphakela i-vacuum → isomisi se-hopper → i-scruder eyodwa yesikulufu→ i-extruder yebhande lombala → isikhunta nesilinganisi → umshini wokulinganisa i-vacuum → ithangi lokupholisa→ umshini wokudonsa → umshini wokusika → isitaki(Umshini wokusonga)

Izici Nezinzuzo

1. Umshini wokwenza ipayipi we-PE uthuthukiswa yi-Polestar ngokusekelwe kubuchwepheshe obuphambili baseYurophu kanye nesipiliyoni se-R & D semishini yepulasitiki iminyaka eminingi, ukuklama okuthuthukisiwe, isakhiwo esinengqondo, ukwethembeka okuphezulu, izinga eliphezulu lokuzenzekelayo komugqa wokukhiqiza ipayipi le-hdpe.

2. I-Extruder enesakhiwo esikhethekile sokuphakela umgqomo ingathuthukisa kakhulu umthamo wokukhipha.

3. Ukulawula okunethezekayo okunembile, i-plasticization enhle, ukusebenza okuzinzile.

4. Umugqa wokukhiqiza wepayipi we-PE wamukela uhlelo lokulawula lwe-PLC, uqaphela ukuvumelanisa nokuzenzakalelayo.

5. I-interface yomuntu nekhompyutha kulula ukuyisebenzisa, ilula futhi inokwethenjelwa.

6. Uhlobo lukabhasikidi oluvunguzayo nolwe-lattice lufile ngokuzikhethela.

7. Ukushintsha izingxenye ezithile zomugqa kungase futhi kubone ukuhlukaniswa okuhlangene kwezingqimba ezimbili kanye nezingqimba eziningi.

8. Ukushintsha izingxenye ezithile zomugqa kungabuye kukhiqize i-PP, amapayipi e-PB.

Idatha Yezobuchwepheshe

| Imodeli | Ibanga lamapayipi (mm) | I-Extruder | Die Head | Amandla aphelele (kW) | Amandla Okukhiphayo (kg/h) |

| I-PE-63 | 16-63 | SJ65 | Indawo eyodwa | 100 | 80-120 |

| I-PE-110 | 20-110 | SJ65 | Indawo eyodwa | 150 | 150-250 |

| I-PE-160 | 50-160 | SJ75 | Indawo eyodwa | 180 | 150-250 |

| I-PE-250 | 75-250 | SJ75 | Indawo eyodwa | 230 | 250-350 |

| I-PE-450 | 160-450 | SJ90 | Indawo eyodwa | 380 | 350-450 |

| I-PE-630 | 250-630 | I-SJ120 | Indawo eyodwa | 550 | 700-800 |

| I-PE-800 | 500-800 | I-SJ150 | Indawo eyodwa | 800 | 900-1100 |

| I-PE-1200 | 710-1200 | I-SJ150 | Indawo eyodwa | 1000 | 1000-1300 |

| I-PE-1600 | 1000-1600 | I-SJ150 | Indawo eyodwa | 1200 | 1200-1500 |

I-Single Screw Extruder

Ngokusekelwe ku-33:1 L/D isilinganiso sokuklama isikulufu, sithuthukise isilinganiso esingu-38:1 L/D. Uma kuqhathaniswa nesilinganiso esingu-33:1, isilinganiso esingu-38:1 sinenzuzo ye-100% yokwenza ipulasitiki, sikhulise umthamo wokukhipha ngo-30%, sinciphise ukusetshenziswa kwamandla size sifike ku-30% futhi sifinyelele cishe ukusebenza kwe-linear extrusion.

I-Simens Touch Screen ne-PLC

Faka isicelo sohlelo oluthuthukiswe inkampani yethu, ube nesiNgisi noma ezinye izilimi ezizofakwa ohlelweni.

Ukwakheka Okuvunguza Kwemigqomo

Ukondla ingxenye yomgqomo sebenzisa isakhiwo esivunguzayo, ukuqinisekisa ukudla okubonakalayo kuzinzile futhi kwandise umthamo wokudla.

Idizayini Ekhethekile Yesikulufu

I-Screw yakhelwe ngesakhiwo esikhethekile, ukuqinisekisa i-plasticization enhle nokuxuba. Izinto ezingancibilikisiwe azikwazi ukudlula le ngxenye yesikulufu.

I-Air Cooled Ceramic Heater

I-Ceramic heater iqinisekisa impilo ende yokusebenza. Lo mklamo owokwandisa indawo lapho i-heater ithintana nomoya. Ukuze ube nomphumela ongcono wokupholisa umoya.

I-Gearbox Esezingeni Eliphezulu

Ukunemba kwegiya kuzoqinisekiswa ibanga elingu-5-6 nomsindo ophansi ongaphansi kuka-75dB. Isakhiwo esihlangene kodwa esinetorque ephezulu.

I-Extrusion Die Head

Ikhanda le-Extrusion die sebenzisa isakhiwo esivunguzayo, isiteshi ngasinye sokugeleza kwezinto sibekwe ngokulinganayo. Isiteshi ngasinye singemva kokwelashwa kokushisa nokupholishwa kwesibuko ukuze kuqinisekiswe ukuthi izinto zihamba kahle. Isakhiwo sekhanda le-Die sihlangene futhi sinikeza ingcindezi ezinzile, njalo ukusuka ku-19 kuya ku-20Mpa. Ngaphansi kwalokhu kucindezela, ikhwalithi yepayipi inhle futhi inomthelela omncane kakhulu kumthamo wokuphuma. Ingakhiqiza ungqimba olulodwa noma ipayipi elendlalelo eziningi.

Idivayisi ehambayo ye-Die Head

Ekhanda likasayizi omkhulu, idivayisi enyakazayo ingayisa ikhanda elishona phambili nangemuva, futhi ilungise ukuphakama kwekhanda lokufa. Ukusebenza kuyashesha futhi kulula.

Idivayisi ye-Die Head Rotary

Ekhanda likasayizi omkhulu elinomshini ojikelezayo, ikhanda lokufa lingazungezisa ngamadigri angama-90. Lapho ushintsha isihlahla, i-mandrel, ikhanda lokufa lizophenduka ama-degree angama-90. Ungasebenzisa i-crane ukuphakamisa nokushintsha isihlahla kanye ne-mandrel. Le ndlela ilula kakhulu.

Idivayisi Eqeda Ukushisa

Lo mshini wengezwa ekhanda ukuze ukhiqize ipayipi elikhulu neliwugqinsi. Ukukhipha ukushisa ngaphakathi kwepayipi kanye nepayipi elipholile ngaphakathi kodonga. Isiphelile esishisiwe singasetshenziswa ukomisa impahla eluhlaza.

Idivayisi yokupholisa ye-Core

Uma sikhiqiza ipayipi elinobubanzi obukhulu nokuqina kodonga, sizosebenzisa amanzi okupholisa noma uwoyela kanye nefeni yokupholisa ukupholisa inkaba yekhanda lokufa ukuze sigweme ukushisa ngokweqile futhi siqinisekise ikhwalithi enhle yezinto ezibonakalayo.

I-Vacuum Tank

Ithangi le-vacuum lisetshenziselwa ukubumba nokupholisa ipayipi, ukuze kufinyelelwe usayizi wepayipi ojwayelekile. Sisebenzisa isakhiwo esinamakamelo amabili. Igumbi lokuqala linobude obufushane, ukuze kuqinisekiswe ukupholisa okuqinile nokusebenza kwe-vacuum. Njengoba i-calibrator ibekwe ngaphambi kwekamelo lokuqala futhi ukuma kwepayipi kwakhiwa ikakhulukazi nge-calibrator, lo mklamo ungaqinisekisa ukwakheka okusheshayo nokungcono nokupholisa kwepayipi.

Ukupholisa Okuqinile Kwesikali

Ngesistimu yokupholisa ekhethekile ye-calibrator, engaba nomphumela ongcono wokupholisa wepayipi futhi uqinisekise isivinini esikhulu. Futhi ngekhwalithi enhle ye-spray nozzle ukuze ube nomthelela ongcono wokupholisa futhi avinjwe kalula ukungcola.

Ukusekela Okungcono Kwepayipi

Epayipini likasayizi omkhulu, usayizi ngamunye unepuleti lawo lokusekela eliyi-semicircular. Lesi sakhiwo singagcina ukuzungeza kwamapayipi kahle kakhulu.

Umthulisi

Sibeka isithulisi ku-vacuum adjust valve ukuze sinciphise umsindo lapho umoya ungena ethangini le-vacuum.

I-Valve Yokusiza Ukucindezela

Ukuvikela ithangi le-vacuum. Lapho idigri ye-vacuum ifinyelela umkhawulo omkhulu, i-valve izovuleka ngokuzenzakalelayo ukuze yehlise i-vacuum degree ukugwema ukuphuka kwethangi. Umkhawulo we-vacuum degree ungashintshwa.

Iphayiphi ye-Double Loop

Iluphu ngayinye enesistimu yokuhlunga amanzi, ukuhlinzeka ngamanzi okupholisa ahlanzekile ngaphakathi kwethangi. I-loop ephindwe kabili futhi iqinisekisa ukuhlinzeka ngokuqhubekayo kwamanzi okupholisa ngaphakathi kwethangi.

Amanzi, Isihlukanisi Segesi

Ukuhlukanisa amanzi amanzi egesi. Igesi iphelile kusukela phezulu. Amanzi agelezela phansi.

Ukulawula Amanzi Okuzenzakalelayo Okugcwele

Ngokulawulwa kokushisa komshini ukuze ube nokulawula okunembile nokuzinzile kokushisa kwamanzi.

I-Whole water inlet kanye nesistimu yokukhipha ilawulwa ngokugcwele okuzenzakalelayo, okuzinzile futhi okuthembekile.

Idivayisi Emaphakathi Yokudonsa amanzi

Wonke amanzi aphuma ethangini levacuum ahlanganiswe futhi axhunywe epayipini elilodwa elingenasici. Xhuma kuphela ipayipi elihlanganisiwe ku-drainage yangaphandle, ukwenza ukusebenza kube lula futhi kusheshe.

Ithangi Lokupholisa

Ithangi lokupholisa lisetshenziselwa ukupholisa ipayipi ngokuqhubekayo.

I-Pipe Clamping Idivayisi

Lolu cingo lungalungisa ukuzungeza kwepayipi uma ipayipi liphuma ethangini le-vacuum.

Isihlungi Sethangi Lamanzi

Ngesihlungi ethangini lamanzi, ukugwema noma yikuphi ukungcola okukhulu lapho amanzi angaphandle engena.

Quality Spray Nozzle

Imilomo yesifutho yekhwalithi inomphumela opholile wokupholisa futhi akulula ukuvinjwa ukungcola.

Idivayisi Yokulungisa I-Pipe Support

Ukusekela ngomsebenzi wokulungisa ukusekela ipayipi elinamadiameter ahlukene.

I-Pipe Support Device

Isetshenziswa ikakhulukazi lapho kukhiqizwa ipayipi elinobubanzi obukhulu nokuqina kodonga. Le divayisi izohlinzeka ngokusekela okwengeziwe kumapayipi asindayo.

Hall Off Unit

Iyunithi ye-Haul off inikeza amandla anele okudonsa ukudonsa ipayipi lizinzile. Ngobukhulu obuhlukahlukene bamapayipi nokujiya, inkampani yethu izokwenza ngendlela oyifisayo isivinini sokudonsa, inani lezinzipho, ubude bokudonsa obusebenzayo. Ukuqinisekisa isivinini sokuphuma kwepayipi lokufanisa kanye nesivinini sokwakheka, futhi gwema ukuguquguquka kwepayipi ngesikhathi sokudonsa.

Hlukanisa i-Traction Motor

I-claw ngayinye ine-traction motor yayo, uma kwenzeka lapho enye i-traction motor iyeka ukusebenza, ezinye izinjini zingakwazi ukusebenza. Ingakhetha i-servo motor ukuze ibe namandla amakhulu okudonsa, isivinini sokudonsa esizinzile kanye nebanga elibanzi lejubane lokudonsa.

Idivayisi Yokulungisa Uzipho

Zonke izinzipho zixhumene komunye nomunye, lapho ulungisa indawo yezizipho ukuze udonse ipayipi ngobukhulu obuhlukahlukene, zonke izinzipho zizohamba ndawonye. Lokhu kuzokwenza ukusebenza kusheshe futhi kube lula.

Idizayini Elungele Umsebenzisi

Nge-Siemens hardware kanye nesoftware esebenziseka kalula eklanywe inkampani yethu. Yiba nomsebenzi ovumelanisiwe ne-extruder, yenza ukusebenza kube lula futhi kusheshe. Futhi ikhasimende lingakhetha kuphela ezinye zezinzipho ezizosebenza ukudonsa amapayipi amancane kakhulu.

Ukulawula Ukucindezela Komoya Okuhlukene

Uzipho ngalunye olunokulawula kwengcindezi yomoya, lunembe kakhudlwana, ukusebenza kulula.

Umsiki

I-Cutter elawulwa yi-Siemens PLC, isebenza ndawonye neyunithi yokudonsa ukuze ibe nokusika okunembile. Ikhasimende lingabeka ubude bepayipi abafuna ukulisika. Izenzo zokuphakela okuningi ukuze kufezwe inqubo eyodwa yokusika (vikela izindwani namasaha, vimbela ku-blade namasaha abambezeleke ipayipi eliwugqinsi futhi ubuso obusikiwe bepayipi bushelelezi).

Idivayisi Yokubamba Okubanzi

Faka idivayisi yokuhlanganisa yendawo yonke kumasayizi amapayipi ahlukene, asikho isidingo sokushintsha idivayisi yokuhlanganisa lapho usayizi wepayipi ushintsha.

I-Saw ne-Blade Iyashintshaniswa

Abanye abasiki bahlome ngakho kokubili isaha neblade. Ukusika ama-saw kanye ne-blade kuyashintshana kumasayizi amapayipi ahlukene. Futhi, isaha nensingo kungasebenza ndawonye ngezidingo ezikhethekile.

Ukulungiswa Kokuphakama Okuphakathi

Ngedivayisi yokulungisa kagesi yedivayisi yokuhlanganisa. Ukusebenza ngokushesha futhi kulula. Ngokushintsha komkhawulo ukuze uqinisekise ukuphepha.

Isitaki

Ukusekela nokwehlisa amapayipi. Ubude besitaki bungenziwa ngendlela oyifisayo.

Ukuvikelwa kwendawo yamapayipi

Nge-roller, ukuvikela indawo yepayipi lapho uhambisa ipayipi.

Ukulungiswa Kokuphakama Okuphakathi

Ngedivayisi elula yokulungisa ukulungisa ukuphakama okuphakathi kwamasayizi amapayipi ahlukene.

Ikhoyili

Ukugoqa ipayipi ku-roller, kulula ukuyigcina nokuhamba. Ivamise ukusetshenziselwa ipayipi elingaphansi kuka-160mm. Yiba nesiteshi esisodwa kanye nesiteshi esiphindwe kabili ongasikhetha.

Ukusetshenziswa kwe-servo motor

Ingakhetha i-servo motor yokugudluzwa kwamapayipi nokujika, ukugudluzwa kwamapayipi anembe kakhudlwana nokungcono.

Izigaba zemikhiqizo

Ufuna Ukungeza Isibhakabhaka Kumklamo Wakho?

Xhumana nathi namuhla ukuze uthole ukubonisana nomklamo.