Umshini Wokukhipha Ipayipi lePlastiki le-PE

Incazelo

I-PE extruder isetshenziswa ku-Polyethylene extrusion ukuze ikhiphe i-PE, i-polyolefin namanye ama-thermoplastics.

Umshini we-polyethylene extrusion ungacubungula zonke izinhlobo zemikhiqizo yepulasitiki ngomshini osizayo othintekayo, njengefilimu, ipayipi, ibha, ipuleti, intambo, iribhoni, ungqimba oluvikelayo lwekhebula, imikhiqizo engenalutho nokunye.

Umshini we-polythene extruder usuthuthukile futhi umthamo wokukhiqiza uphezulu. I-Hdpe ldpe extruder machine plasticization muhle, futhi ukusetshenziswa kwamandla komshini we-ldpe extruder kuphansi. Isebenzisa igiya lezinyo eliqinile ukuze idluliselwe, inenzuzo yomsindo ophansi, ukusebenza okushelelayo, ukulayisha okukhulu, ukuphila isikhathi eside nokunye.

Isicelo

I-PE Amanzi Negesi I-EXTRUSION YAMAPHAYIPHA.

I-PE extruder isetshenziselwa ikakhulukazi i-Polyethylene extrusion yepayipi, ishidi, ibha kanye neminye imikhiqizo yepulasitiki evela ezintweni ze-PE ezifakwe uhlobo oluhlukile lomshini kanye nomfula.

Ku-SJ serial screw extruder, ububanzi besikulufa busuka ku-20 kuye ku-200mm, kanti isikulufu esingu-L/D singu-10-40. Ungakhetha uhlobo lwe-extruder ngokuya ngemikhiqizo yakho, ukucaciswa nomthamo.

Uhlelo lokuphakela lisebenzisa i-YASKAWA .futhi i-main bearing ithatha izingxenye zangempela ze-Japan NSK ezingenisiwe, i-extruder inenani elihle le-money.we futhi sithembisa isevisi enhle kakhulu yangemva kokuthengisa.

Inzuzo Yokuncintisana

Ukuthembeka kokuxhuma: uhlelo lwepayipi ye-polyethylene exhunywe phakathi kokusetshenziswa kwe-hotmelt kagesi, amandla ahlangene angaphezulu kwamandla omzimba wepayipi.

Ukumelana okuhle nomthelela wokushisa okuphansi: izinga lokushisa eliphansi le-polyethylene izinga lokushisa eliphansi lingaba phakathi kwebanga lokushisa elingaphansi kuka-60 kuya ku-60 degrees Celsius ephephile ukusetshenziswa. Ukwakhiwa ebusika, ngenxa yezinto zokwakha, ukumelana nomthelela kuhle, i-tube embrittlement ngeke kwenzeke.

Ukumelana okuhle kokuqhekeka kwengcindezi: I-HDPE inokuzwela kwegebe eliphansi, amandla aphezulu okugunda kanye nekhono elihle kakhulu lokulwa nokuklwebheka, ukumelana nokusebenza kokuqhekeka kwengcindezi yemvelo nakho kugqame kakhulu.

Ukumelana kahle nokugqwala kwamakhemikhali: Ipayipi le-HDPE lingakwazi ukumelana nezinhlobonhlobo zamakhemikhali, ukugqwala, izinto zamakhemikhali ezikhona enhlabathini ngeke zidale noma yikuphi ukuwohloka kwepayipi. I-Polyethylene iyisivikelo sikagesi, ngeke kwenzeke ukubola, ukugqwala noma i-electrochemical corrosion phenomenon; Ngaphezu kwalokho, ngeke kukhuthaze ulwelwe, amagciwane noma ukukhula kwefungal.

Ukumelana nokuguga, impilo ende: okuqukethe u-2% kuya ku-2.5% wokusatshalaliswa okufanayo kwe-carbon black epayipini le-polyethylene kungaba isitoreji sangaphandle noma ukusetshenziswa kweminyaka engama-50, ngeke kube ngaphansi kokulimala kwemisebe ye-ultraviolet.

Ukumelana ne-Abrasion: Ipayipi le-HDPE nokuhlolwa kokuqhathanisa kubonise ukumelana nokugqokwa kwepayipi lensimbi, ipayipi le-HDPE izikhathi ezi-4 ukwedlula ukugqokwa kwepayipi lensimbi. Emkhakheni wokuthuthwa kodaka, uma kuqhathaniswa nepayipi lensimbi, ipayipi le-HDPE linokumelana kangcono nokugqoka, okusho ukuthi ipayipi le-HDPE linempilo ende kanye nomnotho ongcono.

Okuhle okuguquguqukayo: Ipayipi le-HDPE eliguquguqukayo lenza kube lula ukugoba, lisebenza ngokushintsha amapayipi kungaba indlela yokweqa izithiyo ukuya, futhi ezikhathini eziningi, izifakelo zamapayipi eziguquguqukayo zokunciphisa ukusetshenziswa kanye nezindleko zokufaka eziphansi.

Ukumelana nokugeleza: Ipayipi le-HDPE linendawo engaphakathi ebushelelezi, i-Manning coefficient engu-0.009. Ukusebenza okushelelayo nokunganamathelani kuqinisekisa ukuthi ipayipi le-HDPE linomthamo wokudlulisa wamapayipi ojwayelekile, kodwa futhi linciphisa ukulahleka komfutho wepayipi kanye nokusetshenziswa kwamanzi.

Idatha Yezobuchwepheshe

|

Imodeli | L/D | Amandla(kg/h) | Isivinini sokujikeleza (rpm) | Amandla emoto(KW) | Ubude obumaphakathi(mm) |

| SJ25 | 25/1 | 5 | 20-120 | 2.2 | 1000 |

| SJ30 | 25/1 | 10 | 20-180 | 5.5 | 1000 |

| SJ45 | 25-33/1 | 80-100 | 20-150 | 7.5-22 | 1000 |

| SJ65 | 25-33/1 | 150-180 | 20-150 | 55 | 1000 |

| SJ75 | 25-33/1 | 300-350 | 20-150 | 110 | 1100 |

| SJ90 | 25-33/1 | 480-550 | 20-120 | 185 | 1000-1100 |

| I-SJ120 | 25-33/1 | 700-880 | 20-90 | 280 | 1000-1250 |

| I-SJ150 | 25-33/1 | 1000-1300 | 20-75 | 355 | 1000-1300 |

I-Single Screw Extruder

Ngokusekelwe ku-33:1 L/D isilinganiso sokuklama isikulufu, sithuthukise isilinganiso esingu-38:1 L/D. Uma kuqhathaniswa nesilinganiso esingu-33:1, isilinganiso esingu-38:1 sinenzuzo ye-100% yokwenza ipulasitiki, sikhulise umthamo wokukhipha ngo-30%, sinciphise ukusetshenziswa kwamandla size sifike ku-30% futhi sifinyelele cishe ukusebenza kwe-linear extrusion.

I-Simens Touch Screen ne-PLC

Faka isicelo sohlelo oluthuthukiswe inkampani yethu, ube nesiNgisi noma ezinye izilimi ezizofakwa ohlelweni.

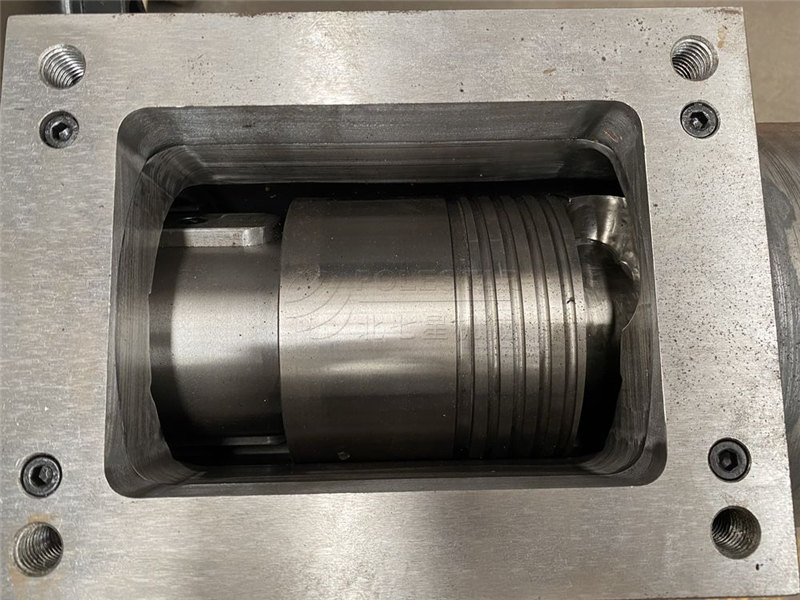

Idizayini Ekhethekile Yesikulufu

I-Screw yakhelwe ngesakhiwo esikhethekile, ukuqinisekisa i-plasticization enhle nokuxuba. Izinto ezingancibilikisiwe azikwazi ukudlula le ngxenye yesikulufu, isikulufu esihle se-plastic extrusion.

Ukwakheka Okuvunguza Kwemigqomo

Ukondla ingxenye yomgqomo sebenzisa isakhiwo esivunguzayo, ukuqinisekisa ukudla okubonakalayo kuzinzile futhi kwandise umthamo wokudla.

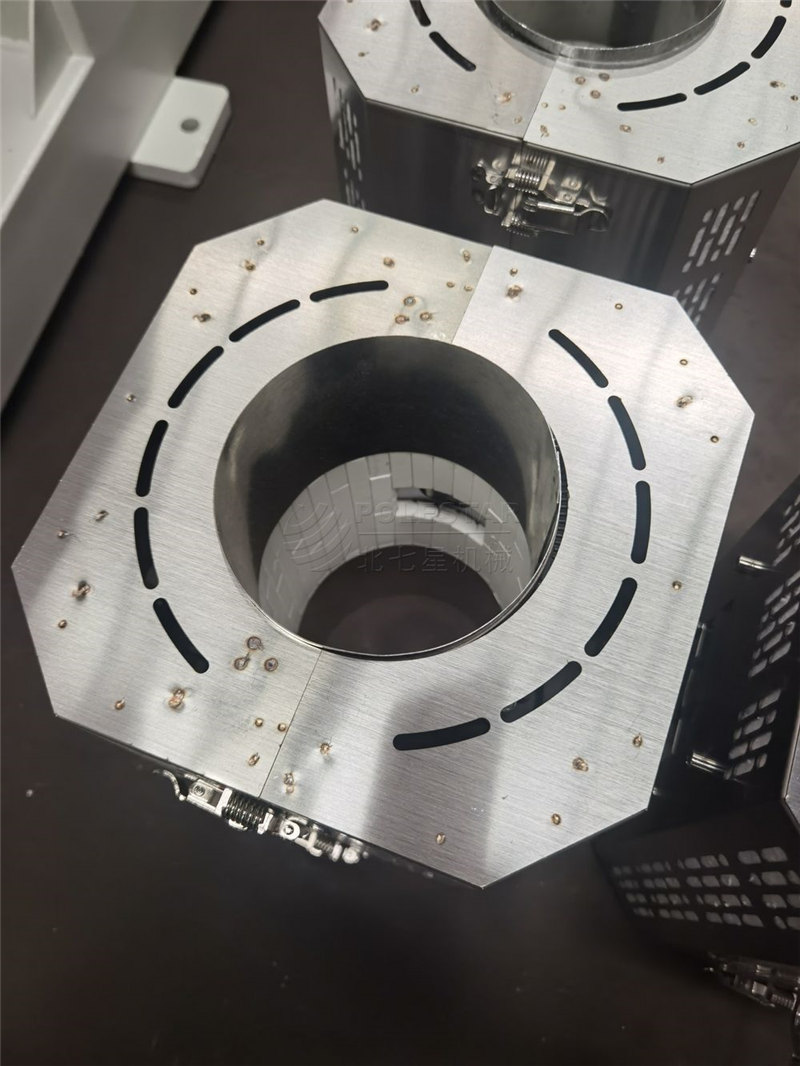

I-Air Cooled Ceramic Heater

I-Ceramic heater iqinisekisa impilo ende yokusebenza. Lo mklamo owokwandisa indawo lapho i-heater ithintana nomoya. Ukuze ube nomphumela ongcono wokupholisa umoya.

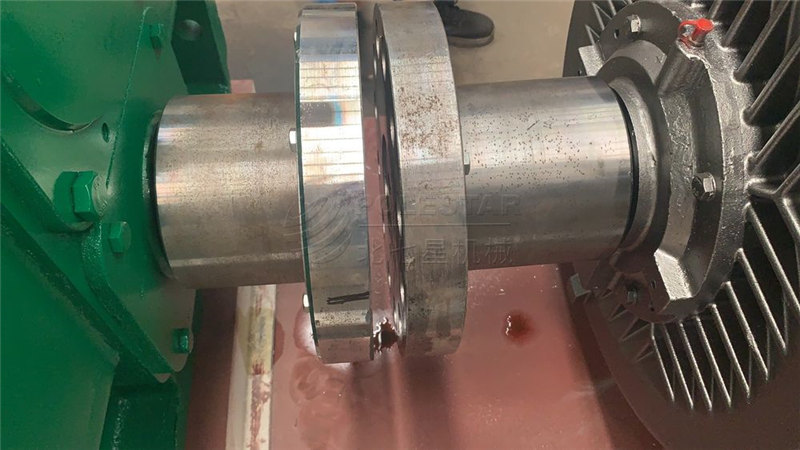

I-Gearbox Esezingeni Eliphezulu

Ukunemba kwegiya kuzoqinisekiswa ibanga elingu-5-6 nomsindo ophansi ongaphansi kuka-75dB. Isakhiwo esihlangene kodwa esinetorque ephezulu.

Izigaba zemikhiqizo

Ufuna Ukungeza Isibhakabhaka Kumklamo Wakho?

Xhumana nathi namuhla ukuze uthole ukubonisana nomklamo.