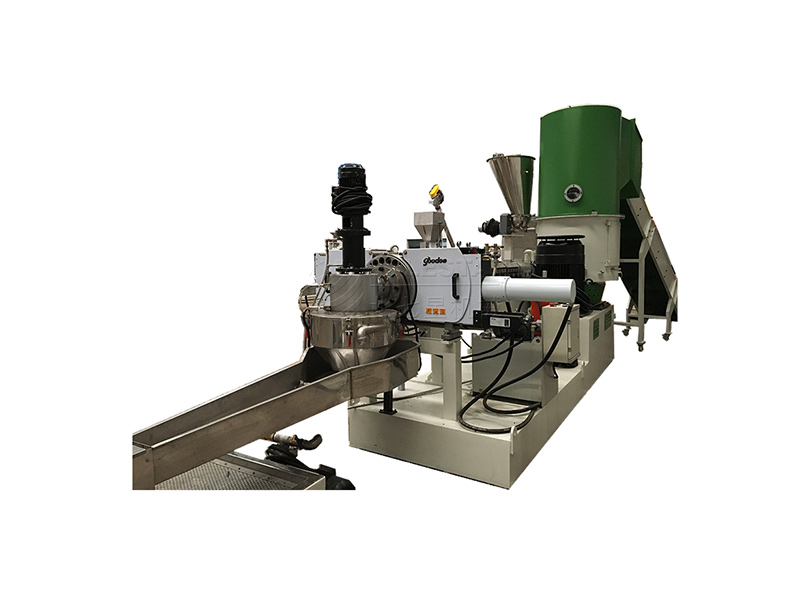

Germany Technology Plastic PE PP Granulating Machine

Imininingwane

I-POLESTAR plastic pelletizer machine / Plastic Granulators ehlinzeka ngokusatshalaliswa kokushisisa okufanayo kanye ne-homogenization ilungele ukukhiqiza ama-pellets epulasitiki enqubweni yokugaywa kabusha. Umshini we-pelletizer wepulasitiki utholakala kumshini owodwa (umshini owodwa kuphela we-extrusion) kanye nokuhlelwa kwesiteji esiphindwe kabili (umshini owodwa oyinhloko we-extrusion kanye nomshini owodwa omncane we-extrusion yesibili). Kunconywa ukuthi kusetshenziswe i-arraignment ephindwe kabili yesiteji sokwenza kabusha inqubo ngenxa yokungcoliswa kwezinto zepulasitiki. Kukhona futhi izinketho ezihlukahlukene zobuchwepheshe bepulasitiki be-granule pelletizing obutholakalayo njengokushintsha isikrini esisizwa nge-hydraulic kanye nesiguquli sesikrini se-double-piston ukuze kuqinisekiswe ukuthi akukho ukuphazamiseka ngesikhathi sokushintsha isikrini. Ibhokisi lethu legiya elithembekile lishayela isikulufa ngokuthula ukuze lixube futhi lihambise ipulasitiki encibilikisiwe emgqonyeni. Isikulufu esenziwe ngensimbi ephathwe ngokukhethekile siqinisekisa ngokumelene nokugqwala nokuhuzuka. Isistimu yokulawula izinga lokushisa ye-PID enomoya noma isistimu yokupholisa amanzi igcina izinga lokushisa elizinzile lokusebenza. "Hot Cut" amanzi-ring die die face pelletizing kanye "Cold Cut" nezindlela ze-strand pelletizing ziyatholakala kuye ngokuthanda kwakho.

Isicelo

Impahla eluhlaza: PE, PP Amafilimu nezikhwama

Umshini wepulasitiki we-granulator / umshini wepulasitiki we-pelletizer / umshini we-pelletizer wepulasitiki one-agglomerator ungasetshenziselwa ifilimu ye-PE / PP noma izikhwama ezilukiweyo ze-PP kanye nokunye ukugaywa kabusha kwe-pellet ye-parabolic, izinto ezisetshenziswayo zizocindezelwa kakhudlwana ngokuhlanganisa okuzoba lula ukuphonswa ukuze kukhishwe ukuze kukhishwe, engafinyelela umthamo omkhulu we-100-100kg/ihora (kuye ngokuthi izidingo zamakhasimende)

Inzuzo Yokuncintisana

1. Izinga eliphezulu lokuzenzakalela, zama kangcono kakhulu ukunciphisa izindleko zakho emsebenzini futhi uqinisekise umthamo ophezulu wokucubungula.

2. Uhlelo lokulawula olunobungane (i-PLC edidiyelwe futhi ehlukanisiwe yokulawula emshinini ngamunye) kanye nephaneli yesikrini sokuthinta, kulula ukuyisebenzisa, ukuqapha kanye nokumisa izimo eziphuthumayo.

3. Zonke izingxenye ezithinta impahla yepulasitiki namanzi zenziwe ngensimbi engagqwali engu-304 ephezulu; Qinisekisa ukuthi akukho ukungcoliswa kwesibili kwama-flakes.

4. Nokia contactor,RKC isilawuli lokushisa

Izici Eziyinhloko

1. Ukulawula okuzenzakalelayo, okusebenziseka kalula, okusebenza kahle kakhulu, ukuvikelwa kwemvelo nokonga amandla;

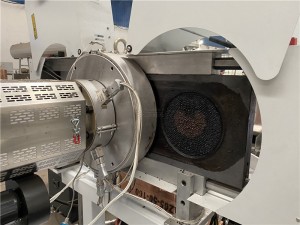

2. Izindlela ezihlukene zokugaya, njenge-strand ebandayo, iringi yamanzi, kanye nangaphansi kwamanzi ngezinto ezihlukahlukene zokusetshenziswa kanye nezidingo zokukhiqiza;

3. Ukushintsha isikrini seziteshi eziningi kanye nomklamo oshintshayo wesikrini kunganciphisa ukusebenza kwezandla futhi kuthuthukise ukusebenza kalula;

4. Isiteji esisodwa nesiphindwe kabili, i-multi-exhaust kanye nohlelo lokuhlunga luqinisekisa izinga eliphezulu nemikhiqizo;

5. Ifanele ukucutshungulwa kwezinto ezihlukahlukene, futhi ingaklama ngokukhethekile umshini wento eyodwa noma izinto ezahlukene, ezinganciphisa izindleko zokutshala izimali zekhasimende.

Idatha Yezobuchwepheshe

Isiteji esisodwa se-agglomeration granulation line

| Imodeli | 70 | 100 | 120 | 150 | 180 |

| Okukhiphayo (kg/h) | 70-120 | 200-250 | 300-400 | 500-600 | 700-850 |

| Ukusetshenziswa kwamandla (kWh/kg) | 700-850 | ||||

| Amandla amakhulu (kW) | 37 | 90 | 110 | 132 | 185 |

| Amandla e-Agglomerator(kW) | 30 | 55 | 75 | 110 | 132 |

| Isikulufa sangaphandle (L/D) | 70(33:1) | 100(30-35:1) | 100(30-35:1) | 100(30-35:1) | 180(30-32:1) |

| Vacuum exhaust | Inketho | ||||

| Ukushintsha isikrini | Ukucushwa okujwayelekile | ||||

| I-granulation yamanzi-ring | Inketho | ||||

| Cold strand granulation | Inketho | ||||

| I-granulation engaphansi kwamanzi | Inketho | ||||

Isiteji esiphindwe kabili se-agglomeration granulation line

| Imodeli | 70+90 | 100+120 | 120+150 | 150+180 | 180+200 |

| Okukhiphayo (kg/h) | 110-180 | 200-300 | 300-450 | 500-650 | 700-850 |

| Ukusetshenziswa kwamandla (kWh/kg) | 0.2-0.35 | ||||

| Amandla amakhulu (kW) | 30+22 | 75+37 | 90+45 | 110+55 | 160+75 |

| Amandla e-Agglomerator(kW) | 30 | 55 | 75 | 110 | 132 |

| Isikulufa sangaphandle (L/D) | 70(25+12:1) | 100(25+12:1) | 120(25+12:1) | 150(25+12:1) | 180(25+12:1) |

| Vacuum exhaust | Inketho | ||||

| Ukushintsha isikrini | 2 amasethi okucushwa okujwayelekile | ||||

| I-granulation yamanzi-ring | Inketho | ||||

| Cold strand granulation | Inketho | ||||

| I-granulation engaphansi kwamanzi | Inketho | ||||

Izigaba zemikhiqizo

Ufuna Ukungeza Isibhakabhaka Kumklamo Wakho?

Xhumana nathi namuhla ukuze uthole ukubonisana nomklamo.