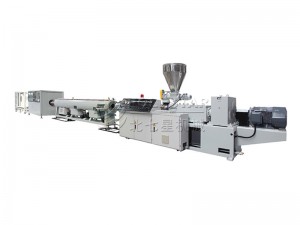

I-Sj Series Single Screw Extruder

Izici

Umshini wokukhipha ipulasitiki oyisikulufa esisodwa ungacubungula zonke izinhlobo zemikhiqizo yepulasitiki enemishini eyisizayo ethintekayo, njengefilimu, ipayipi, induku, ipuleti, intambo, iribhoni, ungqimba oluvikelayo lwekhebula, imikhiqizo engenalutho nokunye. I-screw extruder eyodwa nayo isetshenziswa ekugayeni. Idizayini ye-screw plastic extruder yesikulufa esisodwa isithuthukile, umthamo wokukhiqiza uphakeme, ukwenziwa kwepulasitiki kuhle, futhi ukusetshenziswa kwamandla kuphansi. Lo mshini we-plastic extruder usebenzisa indawo yegiya eliqinile ukuze udlulise. Ama-extruder ethu epulasitiki anezinzuzo eziningi.

Siphinde sikhiqize izinhlobo eziningi ze-extruder zepulasitiki ezifana ne-plastic machine extruder sj25 mini extruder, i-extruder encane, i-lab plastic extruder, i-plastic pellet extruder, i-twin screw extruder, i-PE extruder, i-extruder yepayipi, i-extruder sheet, i-pp extruder, i-Polypropylene Extruder, i-pvc extruder nokunye. ku.

Izinzuzo

1. Umgodi omude phakathi komphimbo wokuphakelayo nesikulufu ukuze uthuthukise okukhiphayo kakhulu

2. Uhlelo olunembile lokulawula izinga lokushisa esigabeni sokuphakelayo ukuze lufane namapulasitiki ahlukene

3. Idizayini yesikulufu esiyingqayizivele ukuze kuzuzwe ipulasitiki ephezulu nekhwalithi yemikhiqizo

4. I-gearbox yebhalansi ephezulu ye-torsion ukuze ibone ukusebenza okuzinzile

5. Uhlaka lomumo ka-H lokunciphisa ukudlidliza

6. Iphaneli yokusebenza ye-PLC ukuze uqinisekise ukuvumelanisa

7. Ukongiwa kwamandla, kulula ukugcinwa

Idatha Yezobuchwepheshe

|

Imodeli | L/D | Amandla(kg/h) | Isivinini sokujikeleza (rpm) | Amandla emoto(KW) | Ubude obumaphakathi(mm) |

| SJ25 | 25/1 | 5 | 20-120 | 2.2 | 1000 |

| SJ30 | 25/1 | 10 | 20-180 | 5.5 | 1000 |

| SJ45 | 25-33/1 | 80-100 | 20-150 | 7.5-22 | 1000 |

| SJ65 | 25-33/1 | 150-180 | 20-150 | 55 | 1000 |

| SJ75 | 25-33/1 | 300-350 | 20-150 | 110 | 1100 |

| SJ90 | 25-33/1 | 480-550 | 20-120 | 185 | 1000-1100 |

| I-SJ120 | 25-33/1 | 700-880 | 20-90 | 280 | 1000-1250 |

| I-SJ150 | 25-33/1 | 1000-1300 | 20-75 | 355 | 1000-1300 |

I-Single Screw Extruder

Ngokusekelwe ku-33:1 L/D isilinganiso sokuklama isikulufu, sithuthukise isilinganiso esingu-38:1 L/D. Uma kuqhathaniswa nesilinganiso esingu-33:1, isilinganiso esingu-38:1 sinenzuzo ye-100% yokwenza ipulasitiki, sikhulise umthamo wokukhipha ngo-30%, sinciphise ukusetshenziswa kwamandla size sifike ku-30% futhi sifinyelele cishe ukusebenza kwe-linear extrusion.

I-Simens Touch Screen ne-PLC

Faka isicelo sohlelo oluthuthukiswe inkampani yethu, ube nesiNgisi noma ezinye izilimi ezizofakwa ohlelweni.

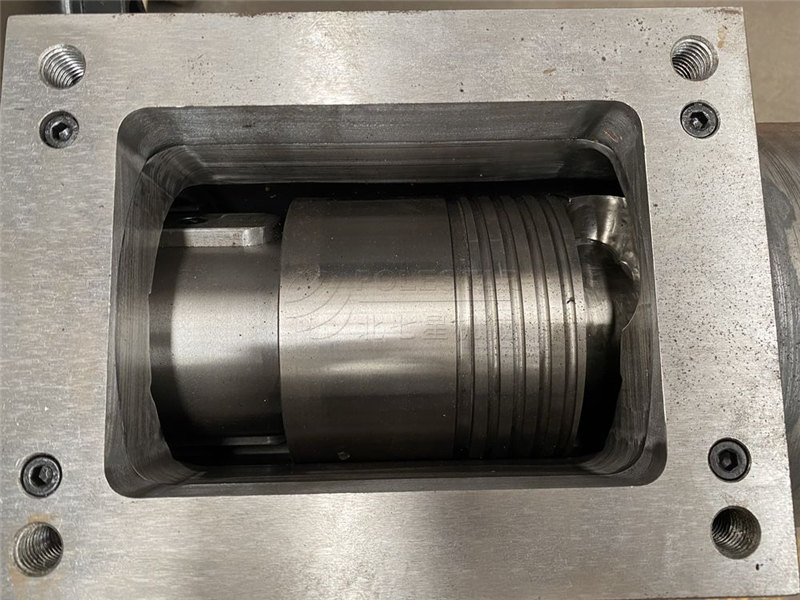

Idizayini Ekhethekile Yesikulufu

I-Screw yakhelwe ngesakhiwo esikhethekile, ukuqinisekisa i-plasticization enhle nokuxuba. Izinto ezingancibilikisiwe azikwazi ukudlula le ngxenye yesikulufu, isikulufu esihle se-plastic extrusion.

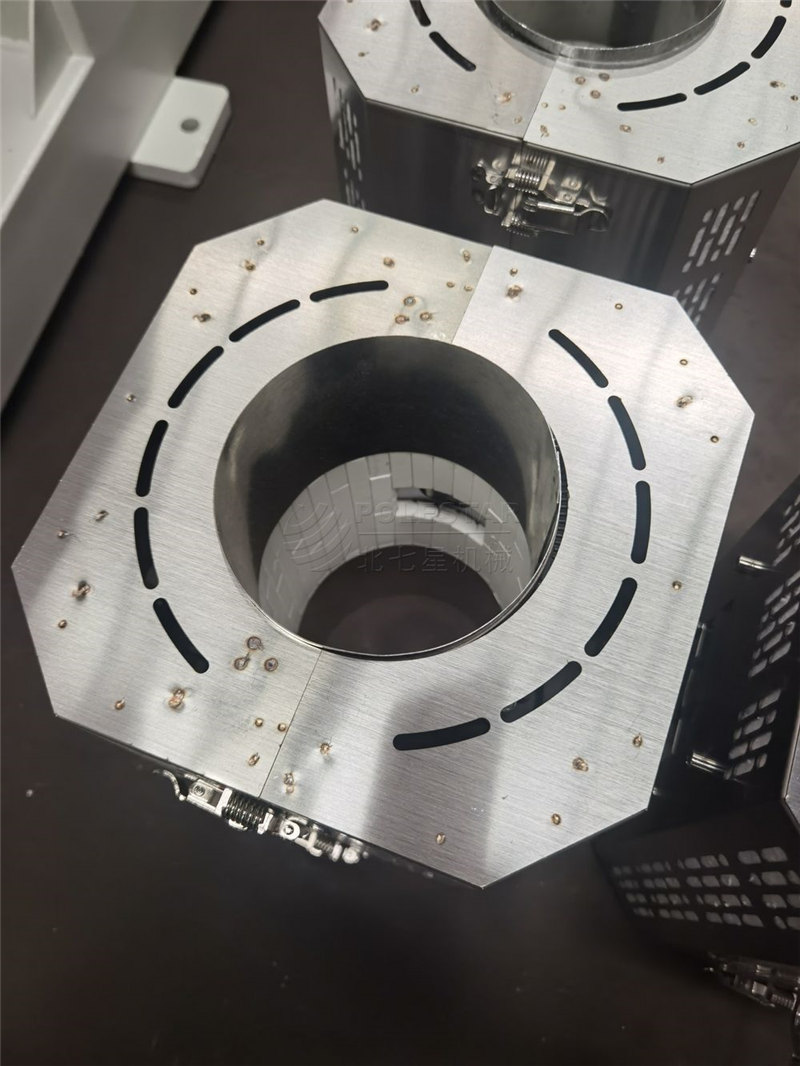

Ukwakheka Okuvunguza Kwemigqomo

Ukondla ingxenye yomgqomo sebenzisa isakhiwo esivunguzayo, ukuqinisekisa ukudla okubonakalayo kuzinzile futhi kwandise umthamo wokudla.

I-Air Cooled Ceramic Heater

I-Ceramic heater iqinisekisa impilo ende yokusebenza. Lo mklamo owokwandisa indawo lapho i-heater ithintana nomoya. Ukuze ube nomphumela ongcono wokupholisa umoya.

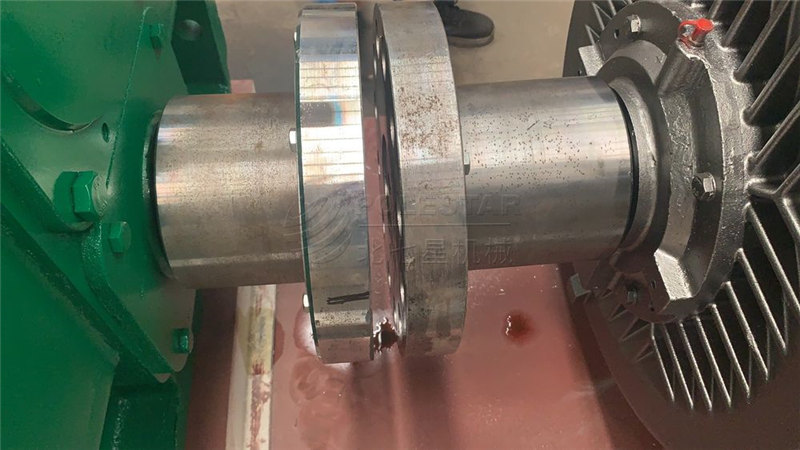

I-Gearbox Esezingeni Eliphezulu

Ukunemba kwegiya kuzoqinisekiswa ibanga elingu-5-6 nomsindo ophansi ongaphansi kuka-75dB. Isakhiwo esihlangene kodwa esinetorque ephezulu.

Izigaba zemikhiqizo

Ufuna Ukungeza Isibhakabhaka Kumklamo Wakho?

Xhumana nathi namuhla ukuze uthole ukubonisana nomklamo.