Uchungechunge lwe-SJZ I-Conical Twin Screw Extruder

Izici

I-SJZ series twin screw extruder ebizwa nangokuthi i-PVC extruder inezinzuzo ezinjengokukhipha ngenkani, ikhwalithi ephezulu, ukuguquguquka okubanzi, impilo ende yokusebenza, isivinini esiphansi sokugunda, ukubola okunzima, ukuhlanganisa okuhle nomphumela we-plasticization, kanye nokubunjwa okuqondile kwezinto eziyimpushana njll. amayunithi okucubungula aqinisekisa izinqubo ezinzile kanye nokukhiqizwa okuthembeke kakhulu ezinhlelweni eziningi ezahlukene. Umshini we-twin screw extruder unomphumela ophezulu, ikhwalithi yomkhiqizo enhle kakhulu kanye nesilinganiso sokusebenza esivelele-phezu kwalo lonke ibanga lokusebenza.

Lo mshini we-pvc conical twin screw extruder, umshini we-pvc extruder ulungele ukuhambisana nomugqa wokukhiqiza wepayipi lepulasitiki, ipuleti nephrofayili nokunye.

Siphinde futhi sikhiqize ezinye izinsimbi zepulasitiki ezifana ne-plastic single screw extruder, i-120mm single screw extruder, i-pvc extruder, i-plastic pellet extruder, i-pp extruder, i-plastic extruder eyenziwe kabusha, i-extruder encane, i-lab plastic extruder nokunye.

Izinzuzo

1.Itholakala ku-PVC eqinile nethambile ihlanganisa i-C-PVC

2.Unique isikulufa design ukuze kuzuzwe plasticizing ephakeme kanye nemikhiqizo izinga

3.Core self-circulation lokushisa lokushisa isikulufa. Isistimu yokulawula izinga lokushisa enembe kakhudlwana

I-4.Gearbox yebhalansi ephezulu ye-torsion ukuze ibone ukusebenza okuzinzile, izinga lokushisa eliphansi likawoyela elitholakalayo

5.I-automatic and ebonakalayo circulation system of lubricant on gear box

Uhlaka lomumo ongu-6.H ukuze kwehliswe ukudlidliza

Iphaneli yokusebenza ye-7.PLC yokuqinisekisa ukuvumelanisa.

8.Ukongiwa kwamandla, kulula ukuwenza

Idatha Yezobuchwepheshe

| Imodeli | SJZ51 | SJZ65 | SJZ80 | I-SJZ92 | I-SJZ105 |

| Isikulufu i-DIA(mm) | 51/105 | 65/132 | 80/156 | 92/188 | 105/216 |

| Ingxenye yesikulufu | 2 | 2 | 2 | 2 | 2 |

| Isikulufu indlela | Ngokuphambene nangaphandle | ||||

| Isivinini se-screw (rpm) | 1-32 | 1-34.7 | 1-36.9 | 1-32.9 | 1-32 |

| Ubude besikulufa(mm) | 1070 | 1440 | 1800 | 2500 | 3330 |

| Isakhiwo | I-conical mesh | ||||

| Amandla emoto amakhulu(kw) | 18.5 | 37 | 55 | 110 | 185 |

| Amandla aphelele(kw) | 40 | 67 | 90 | 140 | 255 |

| Okukhiphayo(ubukhulu: kg/h) | 120 | 250 | 360 | 800 | 1450 |

| Iqoqo lendawo yokushisisa imiphongolo | 4 | 4 | 4 | 5 | 6 |

| Umphakeli | I-Screw dosing | ||||

| Ubude obumaphakathi bomshini(mm) | 1000 | 1000 | 1000 | 1100 | 1300 |

I-Twin Screw Extruder

Kokubili i-conical twin screw extruder kanye ne-parallel twin screw extruder ingasetshenziswa ukukhiqiza ipayipi le-PVC. Ngobuchwepheshe bamuva, ukwehlisa amandla nokuqinisekisa umthamo. Ngokusho kwefomula ehlukile, sihlinzeka ngomklamo ohlukile wesikulufa ukuze kuqinisekiswe umphumela omuhle we-plasticizing kanye nomthamo ophezulu.

I-Simens Touch Screen ne-PLC

Faka isicelo esithuthukiswe yinkampani yethu, ube nesiNgisi noma ezinye izilimi ezizofakwa ohlelweni

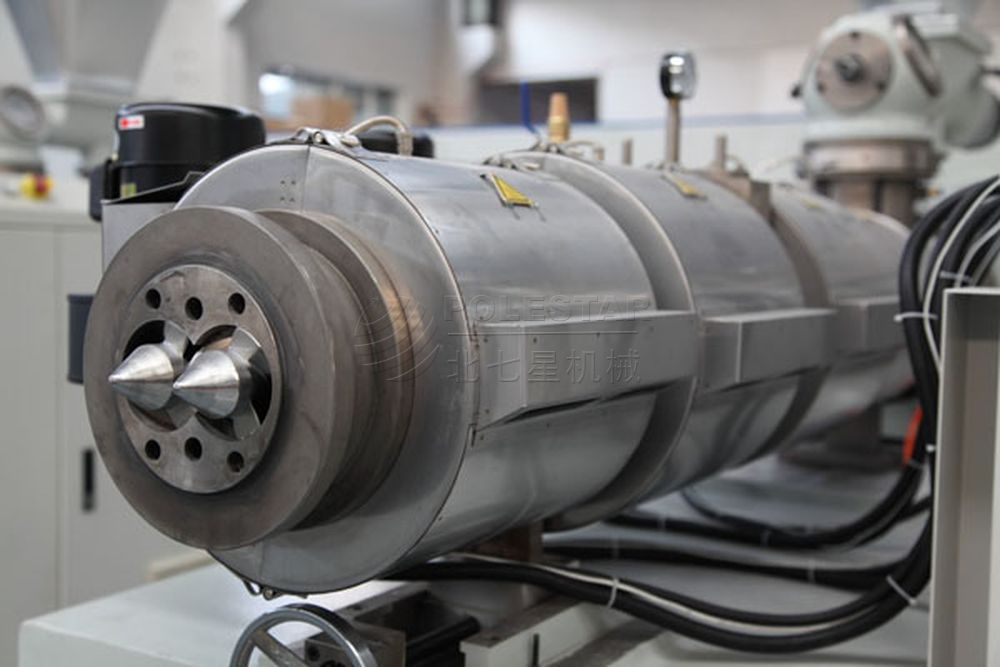

I-Quality Screw kanye ne-Barrel

I-Screw and barrel zisebenzisa insimbi ye-alloy yekhwalithi ephezulu, ecutshungulwa yi-CNC ukuze kuqinisekiswe ikhwalithi, ukunemba kanye nesikhathi eside sesevisi. Izinto ze-Bimetallic zokukhethwa kukho.

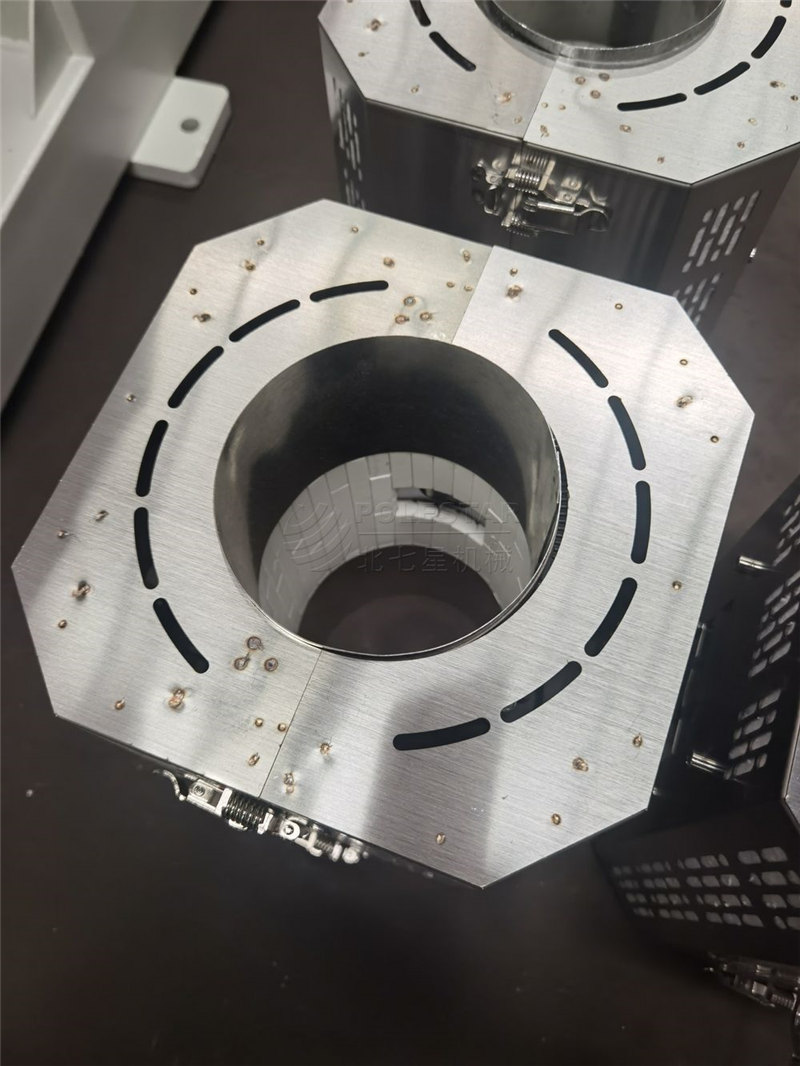

I-Air Cooled Ceramic Heater

I-Ceramic heater iqinisekisa impilo ende yokusebenza. Lo mklamo owokwandisa indawo lapho i-heater ithintana nomoya. Ukuze ube nomphumela ongcono wokupholisa umoya.

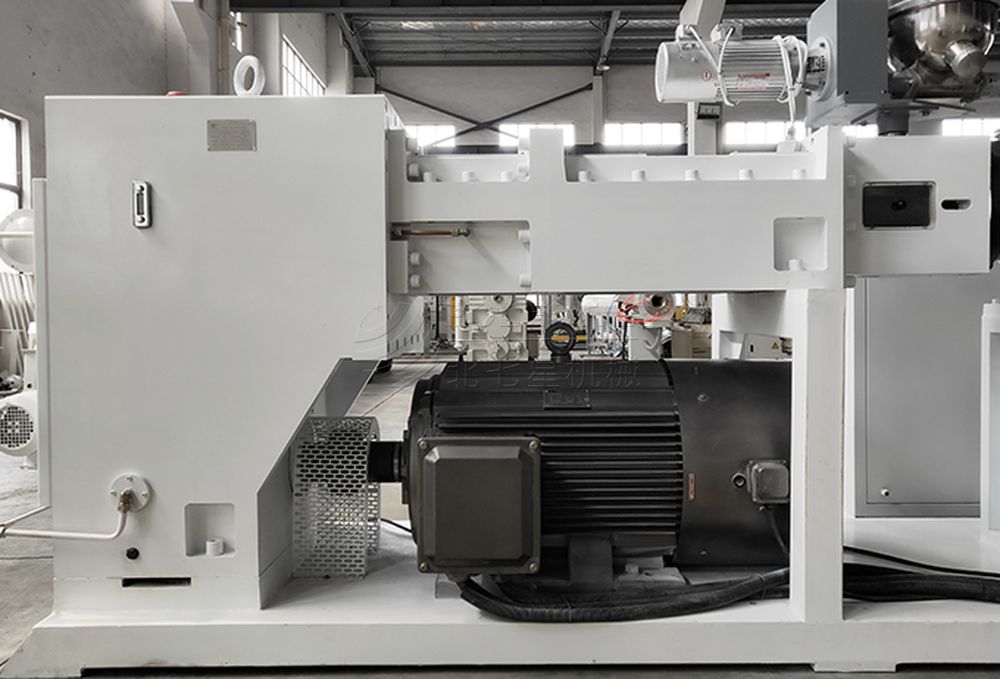

I-Gearbox Yekhwalithi Ephezulu kanye Nebhokisi Lokusabalalisa

Ukunemba kwegiya kuzoqinisekiswa ibanga elingu-5-6 nomsindo ophansi ongaphansi kuka-75dB. Isakhiwo esihlangene kodwa esinetorque ephezulu.

Ukupholisa Okungcono kwe-Gearbox

Ngedivayisi yokupholisa ezimele kanye nephampu kawoyela, ukwenza umphumela ongcono wokupholisa wamafutha okugcoba ngaphakathi kwebhokisi likagiya.

I-Advanced Vacuum System

Isistimu ye-vacuum ehlakaniphile, gcina i-vacuum degree ngaphakathi kwebanga elimisiwe. Uma i-vacuum ifinyelela umkhawulo ophezulu, iphampu izoyeka ukusebenza ukuze yonge amandla futhi izophinda isebenze lapho i-vacuum yehla ngaphansi komkhawulo ophansi.

Easy Cable Connection

Indawo ngayinye yokushisisa, ukupholisa kanye nokubona izinga lokushisa inendawo yayo yokuxhumana kukhabhinethi. Udinga nje ukuxhuma ipulaki ehlanganisiwe esokhethini lekhabhinethi, umsebenzi ulula futhi ulula.

Izigaba zemikhiqizo

Ufuna Ukungeza Isibhakabhaka Kumklamo Wakho?

Xhumana nathi namuhla ukuze uthole ukubonisana nomklamo.